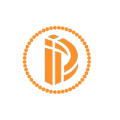

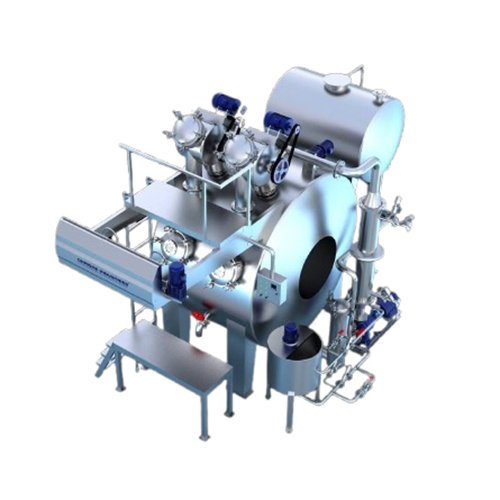

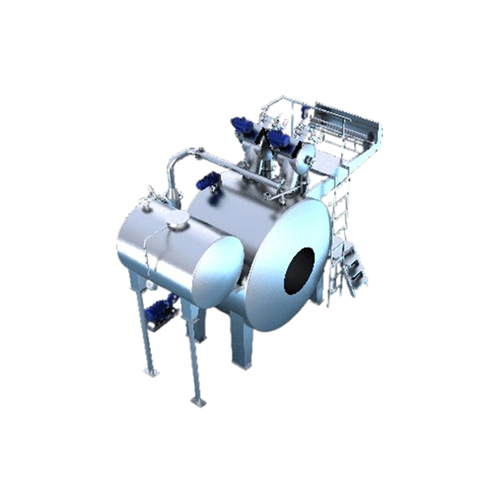

soft flow Dyeing Machine

2050000.00 INR/Unit

Product Details:

- Features Stable operation

- Temperature Range 120 Celsius (oC)

- Pump Type Centrifugal Pump

- Control Type Semi - Automatic

- Power 15 Horsepower (HP)

- Weight 3500 Kilograms (kg)

- Machine Type Dyeing Machine

- Click to View more

X

soft flow Dyeing Machine Price And Quantity

- 1 Unit

- 2050000.00 INR/Unit

soft flow Dyeing Machine Product Specifications

- Stable operation

- 120 Celsius (oC)

- Centrifugal Pump

- Semi - Automatic

- 15 Horsepower (HP)

- 3500 Kilograms (kg)

- Dyeing Machine

- 15 Horsepower (HP)

- soft flow Dyeing Machine

- 600 Kilogram(Kg)

- 2500 Millimeter (mm)

- For Dyeing

- 2

- 600 Kg

soft flow Dyeing Machine Trade Information

- INDIA

- Cash Advance (CA) Cash in Advance (CID)

- 2 Unit Per Month

- 15 Days

- No

- Standard Packing OR As Per Client's Requirement.

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- ISO 9001:2015

Product Description

General Description:

Soft flow dyeing machines are designed for dyeing various types of fabrics, especially delicate and sensitive ones like knits, without causing damage such as pilling, creasing, or distortion. They operate with a gentle flow of dye liquor, often at a low liquor ratio, which contributes to reduced water and chemical consumption, as well as shorter processing times. The fabric is typically circulated in rope form.

Key Features and Exclusive Aspects:

- Soft Flow Nozzle: Employs a specially designed nozzle (often ball-type or cup-type) that ensures a gentle, low-pressure, high-volume flow of dye liquor, minimizing stress on the fabric. Some machines feature adjustable nozzles for versatility.

- Low Liquor Ratio: Operates with a significantly lower liquor-to-fabric ratio (e.g., 1:5, 1:6, or even lower for wet fabric) compared to conventional dyeing machines, leading to savings in water, energy, and chemicals.

- Fabric Transport System: Utilizes a fabric drive reel, often with an AC motor and frequency controller, to move the fabric smoothly through the dye bath. Some advanced designs include twin flow concepts or curved nozzles for even gentler handling.

- Material of Construction: The main vessel and parts in contact with the dye liquor are typically made of high-grade stainless steel (AISI SS 316 or 316L) for excellent corrosion resistance.

- Efficient Heat Exchanger: Designed for rapid and uniform heating and cooling of the dye bath, contributing to shorter dyeing cycles.

- Filtration System: Includes filters that are easy to clean, even during the dyeing process, to maintain liquor quality.

- Automation: Many modern soft flow dyeing machines come with PLC-based automatic control systems for precise control of time, temperature, and other process parameters, ensuring reproducibility and reducing manual intervention.

- Optional Features: These can include flow meters, seam detectors, fully automatic operation with PLCs, color kitchen systems with dosing capabilities, and more.

Technical Specifications (vary by model and manufacturer):

- Capacity: Ranges from small laboratory machines (1-10 kg) to large industrial machines (up to 1000 kg or more per batch).

- Maximum Working Temperature: Typically up to 130-140C, suitable for high-temperature dyeing processes. Some atmospheric soft flow machines operate at lower temperatures (up to 98C) for specific fabric types.

- Fabric GSM (Grams per Square Meter): Can dye fabrics ranging from lightweight (30 g/m) to heavyweight (up to 450 g/m or more), both woven and knitted.

- Liquor Ratio: As mentioned, often very low, starting from 1:5 or 1:6.

- Fabric Speed: Can achieve high fabric speeds (e.g., up to 200-300 m/min, or even higher in some models), depending on the fabric type and machine design.

- Heating/Cooling Rates: Designed for rapid temperature changes (e.g., heating rates of 3-4C/min and cooling rates of 3-4C/min).

- Working Pressure: Typically up to 3-4 kg/cm.

- Power Consumption: Varies significantly based on the machine capacity and features (e.g., from 5 HP to 50 HP or more).

- Number of Tubes: Some machines have multiple dyeing tubes for increased productivity.

Applications:

Soft flow dyeing machines are versatile and suitable for a wide range of fabrics, including:

- Knitted Fabrics: Ideal for delicate knits like cotton jersey, interlock, lycra blends, and hosiery, minimizing the risk of damage.

- Woven Fabrics: Can also process various woven fabrics, including cotton, polyester, and their blends.

- Sensitive Surface Structures: Well-suited for fabrics with delicate surfaces that are prone to pilling or abrasion.

- Natural Fabrics: Effectively dyes natural fibers like cotton, wool, and viscose.

- Synthetic Fabrics: Suitable for dyeing polyester, nylon, acrylic, and their blends.

- Blended Fabrics: Can handle blends like polyester/cotton (T/C), polyester/rayon (T/R), and polyester/wool (T/W).

- Specific Applications: Used for dyeing apparel, terry towels, velour, and elastic fabrics where gentle handling and uniform dyeing are crucial.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email